2023/6/16

Introduction to the Fabric and Function of Disposable Coverall

Disposable coveralls are ubiquitous in various industries, providing a crucial layer of protection for workers against a range of hazards. Understanding the fabrics used and the functionality they offer is vital for selecting the appropriate coverall for a given task. This article will delve into the key aspects of disposable coverall design, focusing on the materials and their protective properties.

Fabric Selection: A Balancing Act

The choice of fabric for a disposable coverall is a complex decision, balancing several critical factors:

Protection Level: The primary function of a coverall is to protect the wearer. The fabric must offer sufficient barrier protection against the specific hazards present. This could include:

Biological hazards: Bacteria, viruses, bodily fluids. In this case, fabrics with high fluid resistance and low permeability are essential.

Chemical hazards: Spills, splashes, or airborne particles of chemicals. The fabric must be resistant to the specific chemicals involved. Consult chemical resistance charts provided by manufacturers.

Particulate hazards: Dust, fibers, or other airborne particles. A high level of filtration is needed, often achieved through microporous membranes or specialized coatings.

Radioactive hazards: Specific fabrics with shielding properties are required in nuclear or medical settings.

Breathability: While protection is paramount, wearer comfort is also crucial. A completely impermeable coverall can lead to overheating, discomfort, and reduced productivity. Therefore, manufacturers strive to balance protection with breathability, often using laminated structures or microporous membranes that allow for some air exchange while maintaining a barrier against hazards.

Durability: The coverall needs to withstand the rigors of the work environment. Tears and punctures can compromise protection. The fabric's tensile strength and tear resistance are key considerations.

Cost: The cost of the fabric directly impacts the overall cost of the coverall. Balancing protection, comfort, and durability with cost is a key challenge for manufacturers.

Common Fabrics and Their Properties

Several fabrics are commonly used in disposable coveralls, each offering a different combination of properties:

Polypropylene (PP): A common choice due to its low cost, good strength, and water resistance. Often used in applications where protection against light splashes or dust is sufficient. However, it generally offers lower breathability than other options.

Polyethylene (PE): Similar to polypropylene in cost and strength but offers even lower breathability. Often used for basic protection against light splashes.

SMS (Spunbond Meltblown Spunbond): A three-layer nonwoven fabric. The meltblown middle layer provides excellent filtration and barrier properties, while the spunbond outer layers offer strength and durability. This is a popular choice for applications requiring higher levels of protection against particulate matter and light liquid splashes.

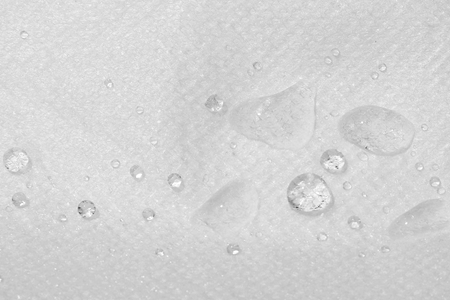

Microporous Film: These films offer excellent barrier protection against liquids and particles, often used in conjunction with other fabrics to enhance protection. They typically have better breathability than solid films like PE or PVC.

Tyvek: A DuPont brand of spunbonded olefin, known for its high tear resistance and good barrier properties against many particulate hazards. It offers a good balance between protection and breathability.

Beyond the Fabric: Design Considerations

The fabric is only one component of a protective coverall. Other design features significantly impact its functionality:

Seams: Properly sealed seams are crucial to prevent leakage. Heat-sealed or taped seams are generally preferred over stitched seams.

Hoods, cuffs, and ankles: Elasticated or self-adhesive closures ensure a tight fit, preventing the entry of contaminants.

Zippers and closures: Durable zippers and secure closures are vital for maintaining the integrity of the coverall.

Conclusion

Selecting the appropriate disposable coverall requires careful consideration of the specific hazards present in the work environment. Understanding the properties of different fabrics and the overall design features is essential to ensure adequate protection and worker safety. Always consult the manufacturer's specifications and safety data sheets to ensure the chosen coverall meets the required protection standards.

WhatsApp

WhatsApp

Send us your message

You can send an email asking for the price and detailed information of this product. We will reply you as soon as we receive your email